Condition monitoring is a process used to monitor and assess the condition of equipment or systems over time. It involves collecting data on various parameters to detect any changes or abnormalities that may indicate a potential failure or performance degradation.

The primary goal of condition monitoring is to identify potential issues at an early stage, allowing for proactive maintenance or corrective actions to be taken before a failure occurs. By continuously monitoring equipment, condition monitoring helps optimize maintenance strategies, reduce downtime, and extend the lifespan of assets.

Condition monitoring typically involves the following steps:

- Data Collection

- Data Analysis

- Condition Assessment

- Maintenance Actions

Condition monitoring is commonly used in various industries, including manufacturing, power generation, oil and gas, transportation, and others. It is particularly valuable for critical equipment and systems where failures can lead to significant operational disruptions, safety risks, or costly repairs.

Overall, condition monitoring enables organizations to move from reactive maintenance (fixing things after they break) to proactive and predictive maintenance (addressing issues before they escalate). This approach helps optimize operational efficiency, reduce maintenance costs, and improve overall asset reliability.

Level measurement in a tank:

The ultrasonic sensor measures the height of the fluid and transfers this as an analog value. Foam or foreign objects cause the amount of reflected sound to be reduced, thus making measurement more difficult. Before this becomes impossible due to further foam formation, the sensor generates an alarm.

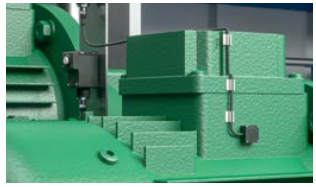

Vibration measurement on a motor:

The sensor measures the vibration on the surface of motors. If it is too large, the cloud generates an alarm. The sensor signals are transferred to a gateway with the wireless node or via RS485. Optional battery operation enables retrofitting without the need for additional cables. Temperature monitoring is also possible with this sensor.

Measurement of air humidity and temperature in a storage room:

The sensor measures the air humidity and temperature in storage rooms. The actual values are transferred via the wireless node. An alarm is generated if the limit values are undershot or exceeded. Optional battery operation enables retrofitting without the need for additional cables.