Programmable Logic Controller (PLC) and a Direct Digital Controller (DDC) are both used to automate and control industrial processes, but they have some differences in terms of their advantages and applications.

Advantages of PLC vs DDC:

- Flexibility

- Reliability

- Modularity

- Scalability

- Integration

DDCs are typically used in building automation applications and offer advantages such as ease of installation, energy efficiency, and the ability to control multiple systems with a single controller.

However, they may not offer the same level of flexibility and scalability as a PLC, especially in industrial applications that require complex control and automation functions.

Why PLC is Better Option than DDC?

- Direct Digital Controller (DDC)

- Designed for Lowest First Cost

- High Post Sale Support Costs

- Limited Post Sale Support Options

- Minimal Tools (Training) Allowing End User to Self-Support Installed base.

Programmable Logic Controller (PLC)

-Designed for Lowest Life Cycle Costs

-Low Post Sale Support Costs

-Multiple Post Sale Support Options

- End User staff

- Local System Providers

-Control System is core to making widgets and End User supportability is an ante

- Open Programming

- Open Training

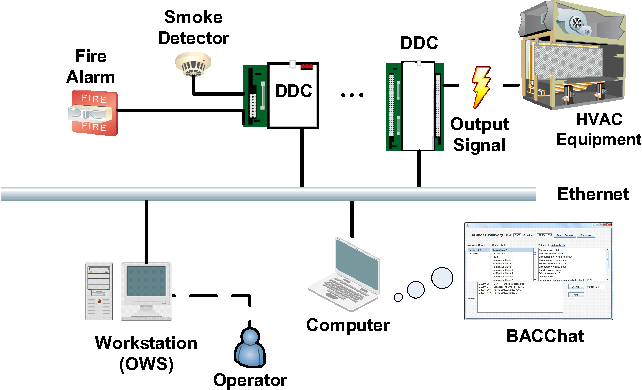

Sample DDC Schematic Drawing

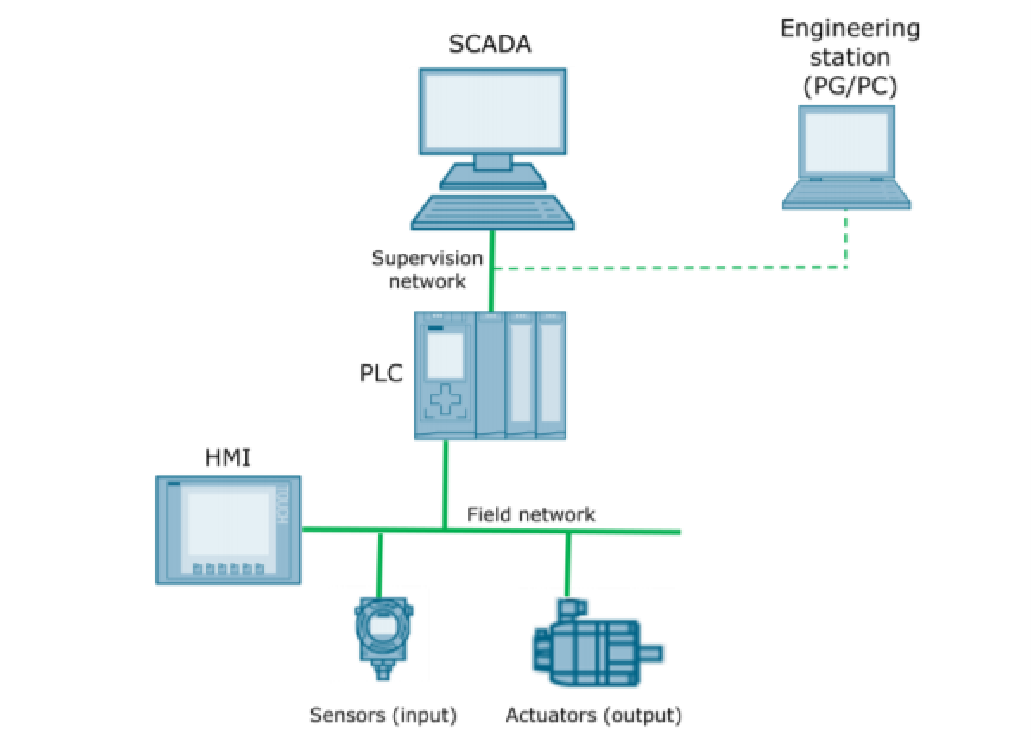

Sample PLC Schematic Drawing